Support

Support

You can check below matters.

- Make sure if proper COM port is assigned for IR-USB01. You can check this on your device manager of Windows. If COM port assigned properly, you can find COM port number on the manager software.

- Check if proper power(7.4V or 12V according to your actuator spec) for actuator is supplied to the green power port of IR-USB01. Without actuator power, software cannot detect the actuator.

- Make sure if you are using Micro 5pin USB cable which supports data transfer. Some USB cable only support charging and you are not able to use this cable for IR-USB01.

- You can refer to the software user manual for more detailed information.

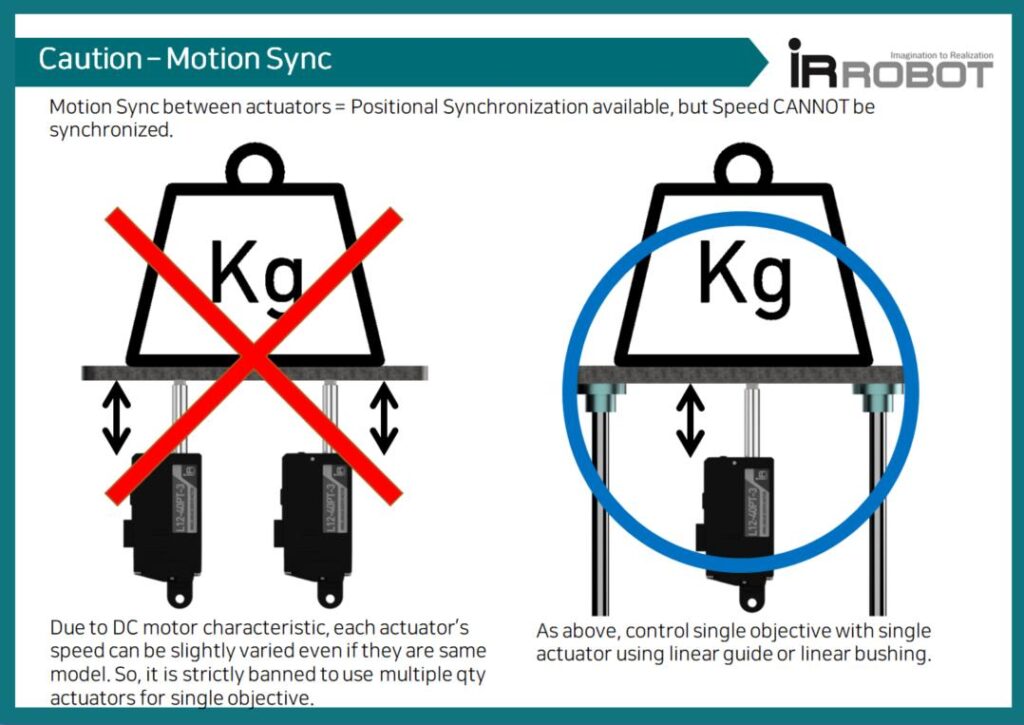

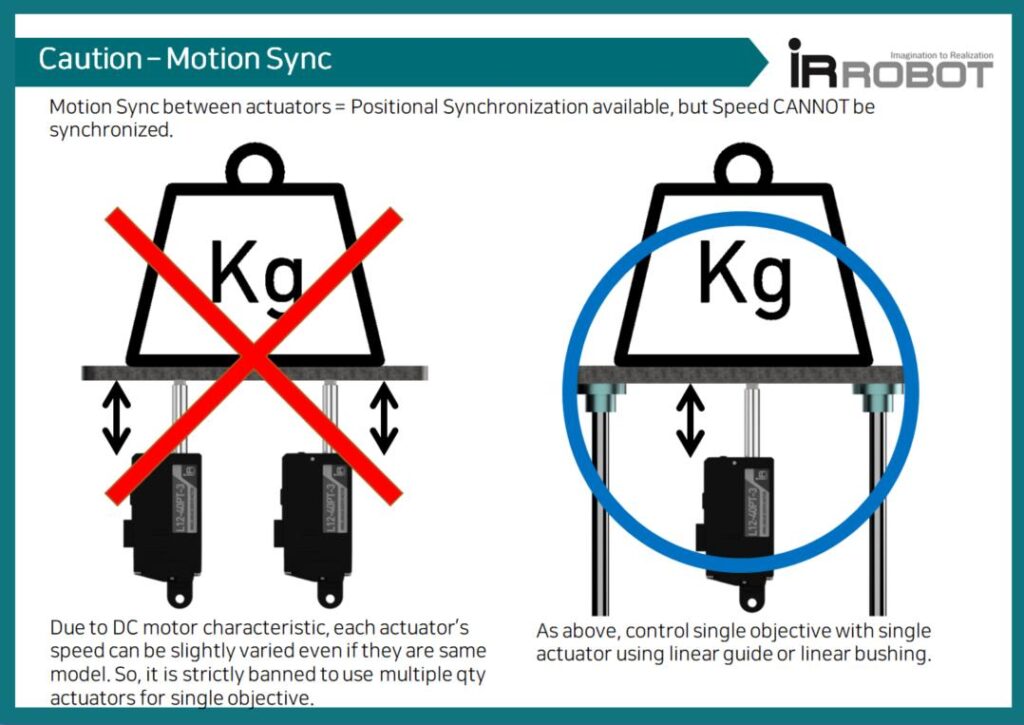

No, you can’t. You can assign ID for each actuator and synchronize them. However, it is for positional synchronization, not for speed. Due to the DC brushed motor’s characteristic, each actuator’s speed can be varied according to mechanical assembly status and DC motor’s tolerance. If you control multiple actuators for same objective, actuators will be under overload condition due to difference of speed. Thus, as shown below picture, control single actuator for single objective. If necessary, you can use linear bushings or linear guide for better alignment.

Here is simple diagram to show how mightyZAP can be connected with PLC

Basic concept will be as below picture.

1 : PLC controller

2 : Communication card (RS-485/422/232C)

3 : Power supply

4 : Voltage regulator (drop to 12V)

- Apply RS-485 compatible mightyZAP (L12-XXF-X series)

- User needs to be program the motion in PLC ladder diagram based on our communication protocol.

- As there are many different PLC brand, please understand that we are not able to provide more pinpointing information for each brand.

- We plan to apply MODBUS compatibility for easier PLC connection in near future.

Yes, it is highly recommended to update the firmware to the latest one as most of update includes improvement of performance or bug fix. To get an update news in timely manner, please subscribe our news letter.

You can contact us at cs@irrobot.com to get a RMA number.

It is a typical symptom when motor is protected by Overload protection feature. Check out if there are any Overload conditions as below and remove overload condition immeditely.

– Discrepancy between position command and mechanical limit

– Too high duty cycle (less than 50% duty cycle is recommended.)

– Heavier load than rated force

The grease should be essentially applied to mightyZAP as it consists of various gears. Small amount of grease can be leaked from the housing, but it does not affect to the normal function.

Yes, you can because mightyZAP supports same PWM signal as conventional R/C. But, please pay attention if you need to deactivate “Overload protection” feature which is basically activated from the factory to prevent unexpected failure during the R/C operation.

You can measure the force of your application using Push-pull gauge.

You can find Molex connectors part number and its drawing on our website. See Digital archive and Drawing tab.

mightyZAP has been developped for indoor application and has IP-54 ingress protection rate. However, we do not recommend to use it under high humid, serious dust condition. User needs to make some protection case if actuator needs to be applied under this serious condition.

Even if we provide basic rod end tip with M3 standard, user may have their own rod end tip according to their requirement. Please remember the standard of rod-end is M3.

You can download each 3D / 2D drawings from our website. Go to Digital archive and see Drawing tab.

No, there should not be transverse force against rod to prevent overload due to the friction. Use Rod end ball bearing or LM guide if it concerns you.

For 27mm stroke version, you can use dedicated metal bracket called IR-MB02 or Rod end bearings, IR-EB01 can be a solution. For 41mm and 56mm stroke version, user can mount the actuator through built-in tapping holes on the housing. If user wants to more flexible mounting, use IR-MB03 metal bracket or IR-EB01 Rod end bearings. For detailed information, download “mounting information” manual from our website.

No. The factor to determine dimension of actuator is something to do with stroke. Under same stroke, there is no difference in dimension due to the different rated force. Because force/speed is determined by gear ratio in same body case. The stronger force, the slower speed.

Using “Motor operating rate” parameter, Stall force level can be adjusted, and speed will be adjusted at the same time.

The stall force is the maximum force of the motor at stall condition and it is 5 times bigger than Rated force.

And please be advised that Rated force will not be changed at any time.

For example, in case of L12-20F-3, its rated force is 20N and the rated force 20N will be maintained regardless motor operating rate.

Use actuator within Rated force range.

Yes, you can. But, Z axis force is slightly different from its rated force, so please refer to the specification chart. And it is highly recommended to apply “Force Off” command after the rod is positioned so that concerned position can be hold by mechanical frictional force. In this case, motor power will be off while communication is still alive. Please refer to the user manual for more detailed information.

No. max stall force is 5 times bigger than rated force. For instance, rated 20N force model(like L12-20PT-3), its max stall force is 100N(10kg). But, you are requested to use them within rated force condition for better lifespan.

No. they are different. Z axis force is weaker than x/y axis force considering gravity. Refer to the spec chart and data sheet.

Considering DC motor characteristic, do not use actuator to push/pull contineously without rest. Also, always check if position command fits with your mechanical limit. There should not be any mechanical hindrance.

You can control force, but it is not based on current feedback. You can only control operating rate of DC motor. We will release force control feature with current feedback when we release 2nd generation of mightyZAP this year.

It is 50μ (0.05mm) to 90μm(0.09mm) according to stroke version. Shorter stroke version has better positional accuracy. For more information, please refer to the specification chart.

No need. because mightyZAP already has a built-in position sensor (potentiometer).

Yes, you can refer to various API and library for C++, C#, Java, Python, Raspberry Pi and Arduino from our website.

Sure. mightyZAP communication is based on half-duplex communication and you can currently get feedback data for position, voltage, temperature and motor operating rate.

Merit point of TTL is user can easily build TTL circuitry on their own embeded board at relatively low cost comparing to RS-485. Demerit point is communication range is shorter than RS-485. (TTL : within 4m)

Merit point of RS-485 is that they are strong against external noise and have far longer communication range.(you can only manage power loss.). Demerit point of RS-485 is that it is a bit costly than TTL when you build your circuitry as RS-485 needs to have dedicated driver IC.

Thus, TTL is recommended for short distance applications having embeded board like medical device and robot. For most of industrial facilites, RS-485 is recommended.

RS-485 has far longer communication range than TTL. For RS485, it reaches several hundreds meters and you can only manage weakened power. For TTL, communication range is about 4m. Data packet including feedback data is not broken within 4m range, so use TTL for short-distance communication.

3.3V or 5V are fine.

Check out if you sent pulse signal constantly (not single signal) until it reaches designated position.

You can choose 7.4V or 12V input voltages lineup. They have different model names. Operating voltage ranges are as below. The lower voltage, the lower force and slower speed.

– 7.4V lineup : 3V~7.4V

– 12V lineup : 7V~12V

No. mightyZAP already has a built-in drive circuit, so you do not need to have it additionally.

Yes, you can. The IR-STS01 is designed based on Arduino hardware and you can control mightyZAP on it. However, note that it is not designed for serious industrial usage, but for casual motion test.

The IR-USB01 is a PC USB interface board which enables you to connect mightyZAP with your PC for various parameter setting or simple motion test on Manager software. (That is, it is an USB to TTL/RS-485 converter for mightyZAP.) So, it is not a controller and highly recommended to buy one when your first purchase of mightyZAP.

We do not have a dedicated controller for our actuators because most of our customers have their own controller such as PLC, PC or embeded board on their application. Thanks to built-in drive circuitry, simply send communication packet from your controller to mightyZAP to control them according to communication protocol we published on the user manual.

Two different protocols. The one is PWM/TTL and the other is RS-485. To get feedback data, user needs to use data communication like TTL or RS-485. (Under PWM mode, user only control position without feedback data).

The duty cycle means the percentage of motor operating time in whole cycle. In other words, 50% duty cycle means that motor should rest 50% of time when motor operates during 50% of time to manage motor lifespan more efficiently. Use actuator under 50% of duty cycle for optimized lifespan. The less duty cycle, the longer lifespan.

It depends on various factors. It will be varied according to duty cycle, load amount, length of stroke, etc. The Duty cycle is the most crucial factor to manage lifespan properly. Recommended duty cycle is less than 50%. For more detailed info for lifecycle, refer to the lifecycle guideline information from our web.

Yes, it is doable. Use IR-USB01 and deactivate “Overload shutdown” setting on manager software. But, remember that actuator will not be protected against overload condition in this case.

Overload protection feature is dafault feature and is activated from the factory. But, if actuator will be exposed to constant overload condition, motor will be stressed and it affects to the lifespan of actuator. When actuator recognizes overload status, blue LED will be flickered and same condition maintains, actuator will be shutdown to protect the actuator (Communication is still alive, but motor power off). In this case, you can revive actuator by supplying power again or sending “Restart” command by data communication. The most important thing is to remove overload condition not to repeat same problem.

Economical line : Relatviely low cost cored motor applied, so price is lower than premium version. But, force is far weaker and has shorter lifespan comparing to premium lineup. (1/10 of Premium lineup lifespan)

Premium line : Heavey duty coreless motor applied which means stronger force and much longer lifespan comparing to economical line. Design form factor is almost same, but stroke is slightly different. Please refer to the drawings of each version.

You can check below matters.

- Make sure if proper COM port is assigned for IR-USB01. You can check this on your device manager of Windows. If COM port assigned properly, you can find COM port number on the manager software.

- Check if proper power(7.4V or 12V according to your actuator spec) for actuator is supplied to the green power port of IR-USB01. Without actuator power, software cannot detect the actuator.

- Make sure if you are using Micro 5pin USB cable which supports data transfer. Some USB cable only support charging and you are not able to use this cable for IR-USB01.

- You can refer to the software user manual for more detailed information.

It is a typical symptom when motor is protected by Overload protection feature. Check out if there are any Overload conditions as below and remove overload condition immeditely.

– Discrepancy between position command and mechanical limit

– Too high duty cycle (less than 50% duty cycle is recommended.)

– Heavier load than rated force

The grease should be essentially applied to mightyZAP as it consists of various gears. Small amount of grease can be leaked from the housing, but it does not affect to the normal function.

Yes, you can because mightyZAP supports same PWM signal as conventional R/C. But, please pay attention if you need to deactivate “Overload protection” feature which is basically activated from the factory to prevent unexpected failure during the R/C operation.

You can measure the force of your application using Push-pull gauge.

The duty cycle means the percentage of motor operating time in whole cycle. In other words, 50% duty cycle means that motor should rest 50% of time when motor operates during 50% of time to manage motor lifespan more efficiently. Use actuator under 50% of duty cycle for optimized lifespan. The less duty cycle, the longer lifespan.

It depends on various factors. It will be varied according to duty cycle, load amount, length of stroke, etc. The Duty cycle is the most crucial factor to manage lifespan properly. Recommended duty cycle is less than 50%. For more detailed info for lifecycle, refer to the lifecycle guideline information from our web.

Yes, it is doable. Use IR-USB01 and deactivate “Overload shutdown” setting on manager software. But, remember that actuator will not be protected against overload condition in this case.

Overload protection feature is dafault feature and is activated from the factory. But, if actuator will be exposed to constant overload condition, motor will be stressed and it affects to the lifespan of actuator. When actuator recognizes overload status, blue LED will be flickered and same condition maintains, actuator will be shutdown to protect the actuator (Communication is still alive, but motor power off). In this case, you can revive actuator by supplying power again or sending “Restart” command by data communication. The most important thing is to remove overload condition not to repeat same problem.

Economical line : Relatviely low cost cored motor applied, so price is lower than premium version. But, force is far weaker and has shorter lifespan comparing to premium lineup. (1/10 of Premium lineup lifespan)

Premium line : Heavey duty coreless motor applied which means stronger force and much longer lifespan comparing to economical line. Design form factor is almost same, but stroke is slightly different. Please refer to the drawings of each version.

You can find Molex connectors part number and its drawing on our website. See Digital archive and Drawing tab.

mightyZAP has been developped for indoor application and has IP-54 ingress protection rate. However, we do not recommend to use it under high humid, serious dust condition. User needs to make some protection case if actuator needs to be applied under this serious condition.

Even if we provide basic rod end tip with M3 standard, user may have their own rod end tip according to their requirement. Please remember the standard of rod-end is M3.

You can download each 3D / 2D drawings from our website. Go to Digital archive and see Drawing tab.

No, there should not be transverse force against rod to prevent overload due to the friction. Use Rod end ball bearing or LM guide if it concerns you.

For 27mm stroke version, you can use dedicated metal bracket called IR-MB02 or Rod end bearings, IR-EB01 can be a solution. For 41mm and 56mm stroke version, user can mount the actuator through built-in tapping holes on the housing. If user wants to more flexible mounting, use IR-MB03 metal bracket or IR-EB01 Rod end bearings. For detailed information, download “mounting information” manual from our website.

No. The factor to determine dimension of actuator is something to do with stroke. Under same stroke, there is no difference in dimension due to the different rated force. Because force/speed is determined by gear ratio in same body case. The stronger force, the slower speed.

No, you can’t. You can assign ID for each actuator and synchronize them. However, it is for positional synchronization, not for speed. Due to the DC brushed motor’s characteristic, each actuator’s speed can be varied according to mechanical assembly status and DC motor’s tolerance. If you control multiple actuators for same objective, actuators will be under overload condition due to difference of speed. Thus, as shown below picture, control single actuator for single objective. If necessary, you can use linear bushings or linear guide for better alignment.

Here is simple diagram to show how mightyZAP can be connected with PLC

Basic concept will be as below picture.

1 : PLC controller

2 : Communication card (RS-485/422/232C)

3 : Power supply

4 : Voltage regulator (drop to 12V)

- Apply RS-485 compatible mightyZAP (L12-XXF-X series)

- User needs to be program the motion in PLC ladder diagram based on our communication protocol.

- As there are many different PLC brand, please understand that we are not able to provide more pinpointing information for each brand.

- We plan to apply MODBUS compatibility for easier PLC connection in near future.

It is 50μ (0.05mm) to 90μm(0.09mm) according to stroke version. Shorter stroke version has better positional accuracy. For more information, please refer to the specification chart.

No need. because mightyZAP already has a built-in position sensor (potentiometer).

Yes, you can refer to various API and library for C++, C#, Java, Python, Raspberry Pi and Arduino from our website.

Sure. mightyZAP communication is based on half-duplex communication and you can currently get feedback data for position, voltage, temperature and motor operating rate.

Merit point of TTL is user can easily build TTL circuitry on their own embeded board at relatively low cost comparing to RS-485. Demerit point is communication range is shorter than RS-485. (TTL : within 4m)

Merit point of RS-485 is that they are strong against external noise and have far longer communication range.(you can only manage power loss.). Demerit point of RS-485 is that it is a bit costly than TTL when you build your circuitry as RS-485 needs to have dedicated driver IC.

Thus, TTL is recommended for short distance applications having embeded board like medical device and robot. For most of industrial facilites, RS-485 is recommended.

RS-485 has far longer communication range than TTL. For RS485, it reaches several hundreds meters and you can only manage weakened power. For TTL, communication range is about 4m. Data packet including feedback data is not broken within 4m range, so use TTL for short-distance communication.

3.3V or 5V are fine.

Check out if you sent pulse signal constantly (not single signal) until it reaches designated position.

You can choose 7.4V or 12V input voltages lineup. They have different model names. Operating voltage ranges are as below. The lower voltage, the lower force and slower speed.

– 7.4V lineup : 3V~7.4V

– 12V lineup : 7V~12V

No. mightyZAP already has a built-in drive circuit, so you do not need to have it additionally.

Yes, you can. The IR-STS01 is designed based on Arduino hardware and you can control mightyZAP on it. However, note that it is not designed for serious industrial usage, but for casual motion test.

The IR-USB01 is a PC USB interface board which enables you to connect mightyZAP with your PC for various parameter setting or simple motion test on Manager software. (That is, it is an USB to TTL/RS-485 converter for mightyZAP.) So, it is not a controller and highly recommended to buy one when your first purchase of mightyZAP.

We do not have a dedicated controller for our actuators because most of our customers have their own controller such as PLC, PC or embeded board on their application. Thanks to built-in drive circuitry, simply send communication packet from your controller to mightyZAP to control them according to communication protocol we published on the user manual.

Two different protocols. The one is PWM/TTL and the other is RS-485. To get feedback data, user needs to use data communication like TTL or RS-485. (Under PWM mode, user only control position without feedback data).

Using “Motor operating rate” parameter, Stall force level can be adjusted, and speed will be adjusted at the same time.

The stall force is the maximum force of the motor at stall condition and it is 5 times bigger than Rated force.

And please be advised that Rated force will not be changed at any time.

For example, in case of L12-20F-3, its rated force is 20N and the rated force 20N will be maintained regardless motor operating rate.

Use actuator within Rated force range.

Yes, you can. But, Z axis force is slightly different from its rated force, so please refer to the specification chart. And it is highly recommended to apply “Force Off” command after the rod is positioned so that concerned position can be hold by mechanical frictional force. In this case, motor power will be off while communication is still alive. Please refer to the user manual for more detailed information.

No. max stall force is 5 times bigger than rated force. For instance, rated 20N force model(like L12-20PT-3), its max stall force is 100N(10kg). But, you are requested to use them within rated force condition for better lifespan.

No. they are different. Z axis force is weaker than x/y axis force considering gravity. Refer to the spec chart and data sheet.

Considering DC motor characteristic, do not use actuator to push/pull contineously without rest. Also, always check if position command fits with your mechanical limit. There should not be any mechanical hindrance.

You can control force, but it is not based on current feedback. You can only control operating rate of DC motor. We will release force control feature with current feedback when we release 2nd generation of mightyZAP this year.